Or How Bodaq Interior Film Is Different from What You Are Used.

Table of Contents

Breaking The Popular Myths.

Let’s debunk three of the most common myths and misunderstandings about vinyl film. Nobody even calls it a vinyl film anymore – it is an architectural interior film made of the new generation of PVC. From manufacturing to installation, Bodaq Interior Films promote a healthy environment and safety, minimizing the release of volatile organic compounds (VOCs) and avoiding other hazardous chemicals.

So, here are the myths that took over people’s minds through the years of hearing or using vinyl.

Myth #1: It is cheap and low quality.

This myth was not unfounded because, in the early 2000s, the architectural vinyl wrap was a simple, cheap, low-quality solution. However, in 2022, the film is a premium surface solution that imitates natural surfaces so precisely that even a keen eye cannot spot a difference. Different businesses use Bodaq interior film because it is a quick and effective way to renovate an existing surface or cover a new one. It helps save an impressive amount of money without drawbacks to the final result.

Also, there are six collections of Bodaq Film – Wood, Metal, Stone & Marble, Solid Colors, Fabric & Leather, and a new one – Heavy-Duty. A variety of patterns in the catalog satisfies every design idea. The only limit is your imagination.

In the pictures below, you can see how the modern interior film looks.

Myth #2: You cannot install the film near hot or humid areas.

It is a myth that may be logical for some kinds of films, especially ones that use old-school manufacturing technologies. We all know that humidity ruins different materials, and it unsticks from surfaces.

However, Bodaq Film uses a new moisture-wicking technology that allows its usage in places with high humidity levels, such as shower stalls. Additionally, the film has antimicrobial and antifungal properties. It is not true about the majority of standard renovation materials.

Also, Bodaq Interior Film meets high-Class A (Class I) fire and smoke ratings – the lowest fire spread rate and minimal smoke production. It means that Bodaq is a perfect surfacing solution for high-risk areas – airports, elevators, healthcare facilities, hospitality amenities, transport, fireplaces, etc.

Myth #3: Thickness determines durability.

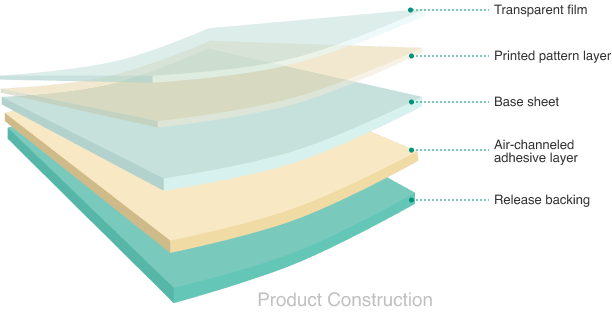

The myth is formed on paper-based materials because you can easily tear the paper. But it is not applicable in the case of interior film because it only has a paper backing that is not involved in the installation. By the way, it is the only waste you will have after the installation.)

The embossed and printed film layer has a simplified air-channeled adhesive made of acrylic plastic. It is also known as polymethyl methacrylate (PMMA). It does not contain potentially harmful bisphenol-A subunits found in polycarbonate. PMMA is a strong but thin and lightweight material.

So, it is a beneficial resurfacing material for elevator enclosures where weight is crucial.

To wrap up, we hope some myths disappear when Bodaq proves its beneficial properties. And it is just a matter of time. Until then, we will be breaking the most popular myths about vinyl film.

Stay tuned and use Bodaq!

Find more information by the links: Catalog | Technical Reports |Why Bodaq | Contact Us